Industrial Furnace

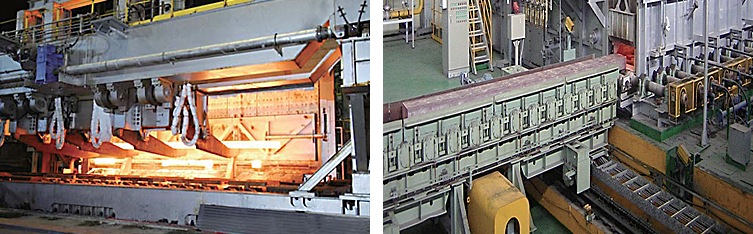

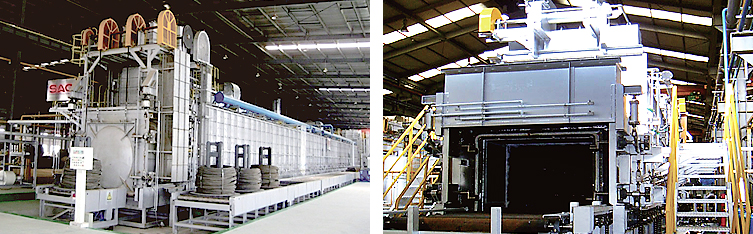

Walking Beam Type Heating Furnace

Application

Application

- Furnace type : Walking beam, Pusher type

- Treatment material : Copper, Copper-Alloy Slab

Features

Features

- Capacity : Max 100Ton/hr

- Temperature : Max 1,100℃

- Heating source : Gas, Oil

Advantages

Advantages

- Furnace temperature control facilities

- Production of high quality products

- Energy saving

- Full automatic system

- High productivity

- Material Temperature uniformity

- High durability

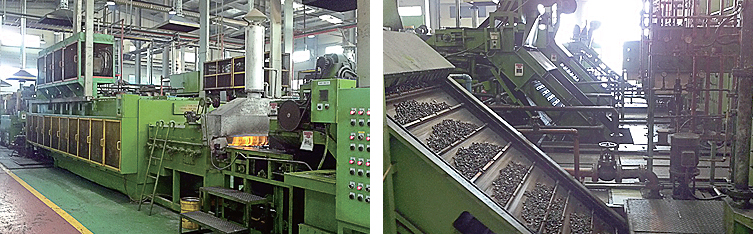

Mesh Belt Type Heat Treatment Furnace

Application

Application

- Carburizing, Quenching & Tempering and

Heat-treatment - Treatment material :

Automobile parts, Fastener etc.

Features

Features

- Capacity : Max 1.5Ton/hr

- Temperature : Max 950 ℃

- Atmospheric Gas : Rx-gas, Methanol

Advantages

Advantages

- High quality of heat treatment

- Full automation system

- Maintenance cost down

- Uniformed temperature

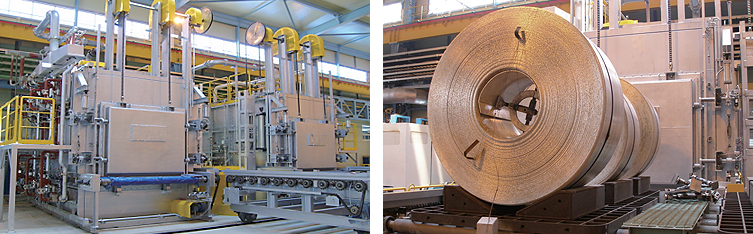

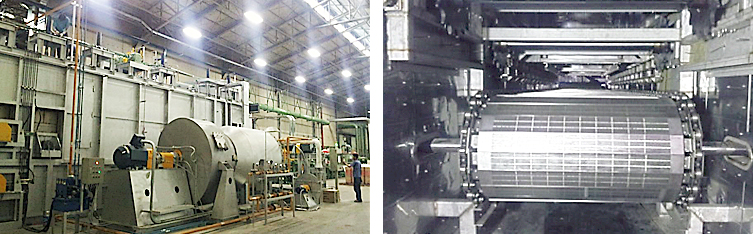

Mg SOF

Application

Application

- Furnace type : Mg soaking

- Treatment material : Mg strip coil

Features

Features

- Capacity : Max 30Ton/ch

- Temperature : Max 600℃

- Heating source : Gas, Heater

- Atmosphere gas : N2 gas

Advantages

Advantages

- Material temperature Uniformity

- Production of high quality products

- More energy saving

- Quality improvement

- High productivity

- Full automatic system

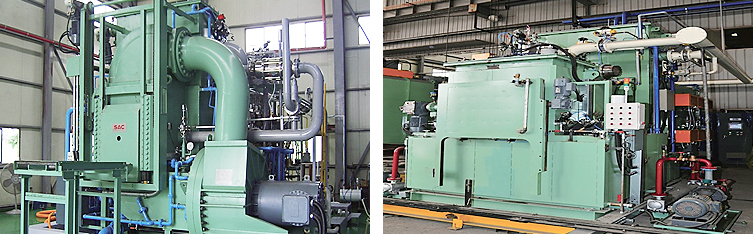

Low Pressure Carburizing (GQ/OQ)

Application

Application

- Mass Production for auto

motive gear and shaft

Features

Features

- Carburizing Temp : 850 ~ 1,050℃

- Carburizing Pressure : 1 ~ 30mbar

- Carburizing Time : 5min ~ 5hr

- Carburizing Depth : 0.3 ~ 3mm

- Gas Quenching : Max 20bar (N2, He)

Advantages

Advantages

- Production of high quality products

- Environmental Protection, non-pollution

- Shortens process time and reduce costs of 35%

- Fully automatic system

- Reducing the Processing time of 30~50%

Foundation

Foundation