SAF/EAF/RF/RSF/PHS/RMHS

INTRODUCTION

Submerged Arc Furnace (SAF) for ferro-alloy produces various kinds of ferro-alloy such as Fe-Mn, Fe-Ni, Si-Mn, Fe-Si and MG-Si melting raw materials down with electrical power.

To make ferro-alloy of high-purity, which is produced by Submerged Arc Furnace (SAF), Electric Arc Furnace (EAF) and Refining Furnace (RF) provides high efficiency of work with improved process.

We have an ability to execute EPCC (Engineering, Procurement, Construction and Commercial) successfully. Moreover, it is possible to supply all the auxiliary utilities required for ferro-alloy plant.

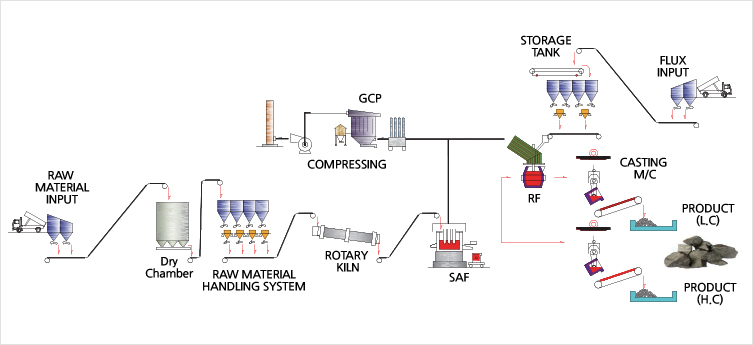

BASIC PROCESS DIAGRAM OF FERRO – ALLOY PLANT

Submerged Arc Furnace

Application

Application

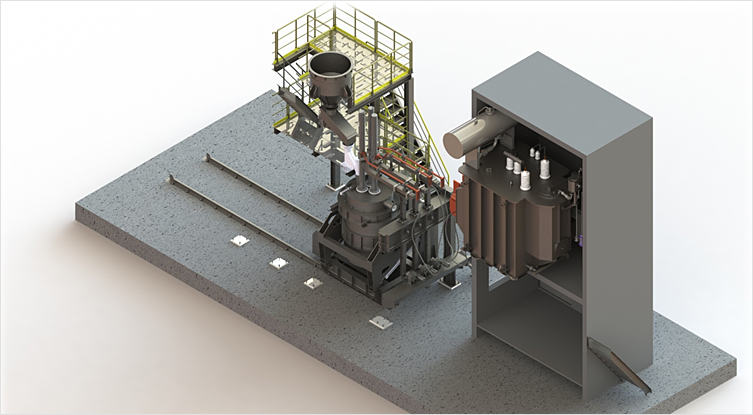

- Rheostatic Electric Furnace Plant for Ferro Alloy

Production - Product : Fe-Mn, Fe-Si, Fe-Cr, Si-Mn MG-Si,

Fe-Ni and Special Alloy, etc.

Features

Features

- Type : Self-Baking Electrodes[Soederberg]

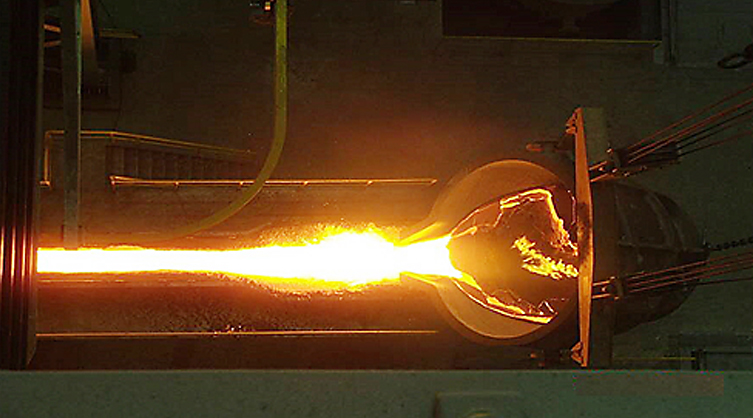

- Tapping method : Tapping & Mud-Gun Type

- Low Noise with Electrodes Column Control

by Hydraulic System

Advantages

Advantages

- Erosion Control & Durability

Improvement with Neutral Refractory - Efficient Power Source Unit

Electric Arc Furnace

Application

Application

- EAF in Prebaked Electrode Type for

re-heating of slag or molten metals

Features

Features

- Type : Pre-Baked Electrode Type

- Control of mast using Hydraulic System

- Swing cover & tilting shell type

Advantages

Advantages

- Simplification of Facility

- Excellent Durability

- Safe & Easy replacement of Electrodes

- Conduct of 3D Design for checking all parts

Refining Furnace

Application

Application

- Production of molten metals with low

carbon out of molten metals with high

carbon

Features

Features

- Type : AOD Type

- Tilting device for Hydraulic System

- Automatic input of raw materials-cooling

water hood

Advantages

Advantages

- Conduct of 3D design for checking all parts

- High operating security

- Extensive automation

- Long service life

- Maintenance-free design

Recycling Slag Furnace

Application

Application

- Production of Mineral Wool from Slag discharged

out of Blast Furnace - Product : Raw materials for the refractory industry

(corundum, smelting magnesia, mineral wool),

Metallurgical plant residue reprocessing and recy

cling (incl. flue dust, scale, slag, salamanders)

Features

Features

- Type : Pre-Baked Electrode Type

- Control of Products in the required

quantity & the fixed temperature

Advantages

Advantages

- Simplification in the process of operation

- Customized Engineering according to

environment of operation

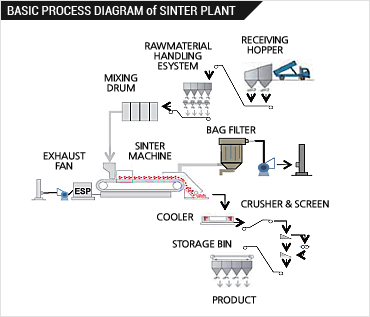

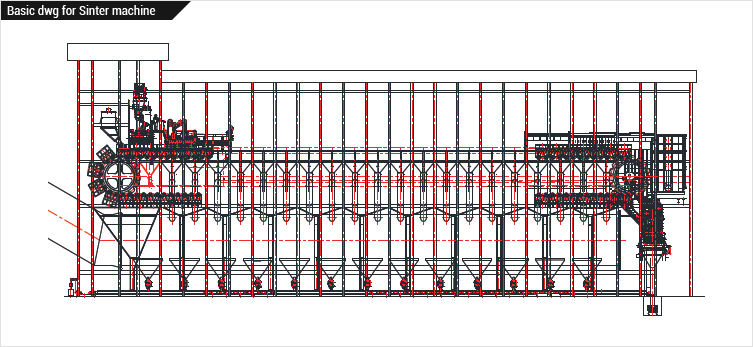

Product Handling System

Application

Application

- Crushing products into a fixed size by casting

the products in liquid state consecutively and

automatic sorting by each size

Features

Features

- Casting Machine

- Crusher

- Screen

- Feeder

- Storage Tank

Advantages

Advantages

- Automatic sorting by sizes of product & storage

- High Speed & Low Costs

- Maintenance-friendly segment design

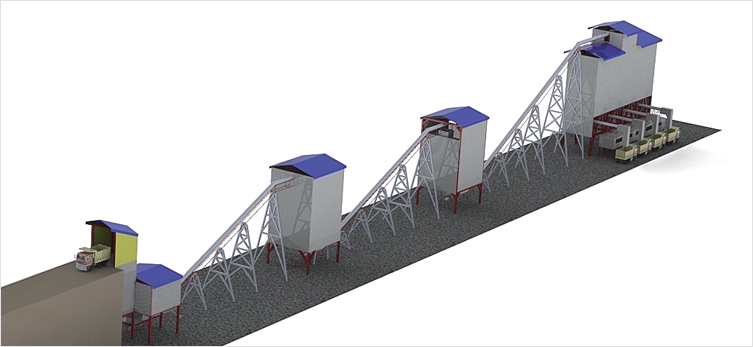

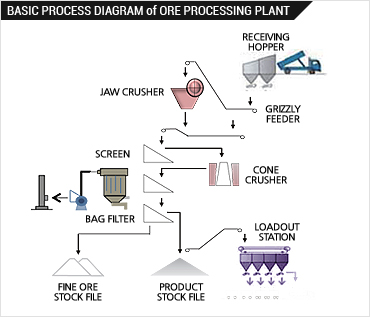

Raw Material Handling System

Application

Application

- Mix of raw materials in Material Balance & automatic

transfer system

Features

Features

- Belt Conveyor

- Day Bin

- Scale Hopper

Advantages

Advantages

- Minimization of dust generation due to local

dust collection - Automatic System