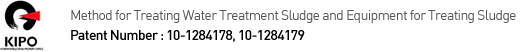

- SAC facilities

oversea sales - Drying

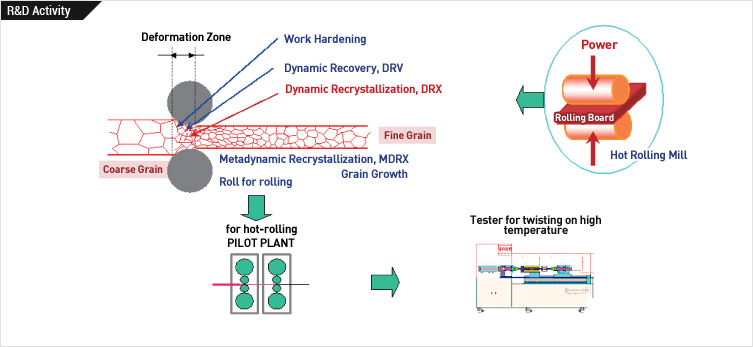

Module

Process - Hot

torsion

tester - Cokes

- Anthracite

Briquette - Manganese

Dioxide - Calcined

Anthracite

Coal

SAC facilities oversea sales

Ferro Alloy PLANT (Fe-Mn/Fe-Si/Fe-Ni)

Ferro Alloy PLANT (Fe-Mn/Fe-Si/Fe-Ni)

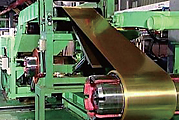

PROCESS LINE

PROCESS LINE

-

CGL/PGL/ACL

CGL/PGL/ACL

-

BAL/APL

BAL/APL

-

Copper Strip AP

Copper Strip AP

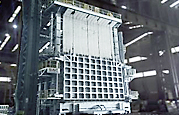

INDUSTRIAL FURNACE

INDUSTRIAL FURNACE

-

CONTINUOUS FURNACE

CONTINUOUS FURNACE

-

APL

APL

-

AL-MELTING FURNACE

AL-MELTING FURNACE

-

NGOT HEAT FURNACE

NGOT HEAT FURNACE

-

MOTOR CORE ANNEALING

MOTOR CORE ANNEALING

FURNACE -

SHEET POAMING FURNACE

SHEET POAMING FURNACE

-

BOTTOM CAR TYPE FURNACE

BOTTOM CAR TYPE FURNACE

-

BOTTOM CAR TYPE FURNACE

BOTTOM CAR TYPE FURNACE

-

LEAD FRAME FURNACE

LEAD FRAME FURNACE

-

GAS CARBURIZING FURNACE

GAS CARBURIZING FURNACE

-

COIN ANNEALING FURNACE

COIN ANNEALING FURNACE

-

AUS-TEMPERING FURNACE

AUS-TEMPERING FURNACE